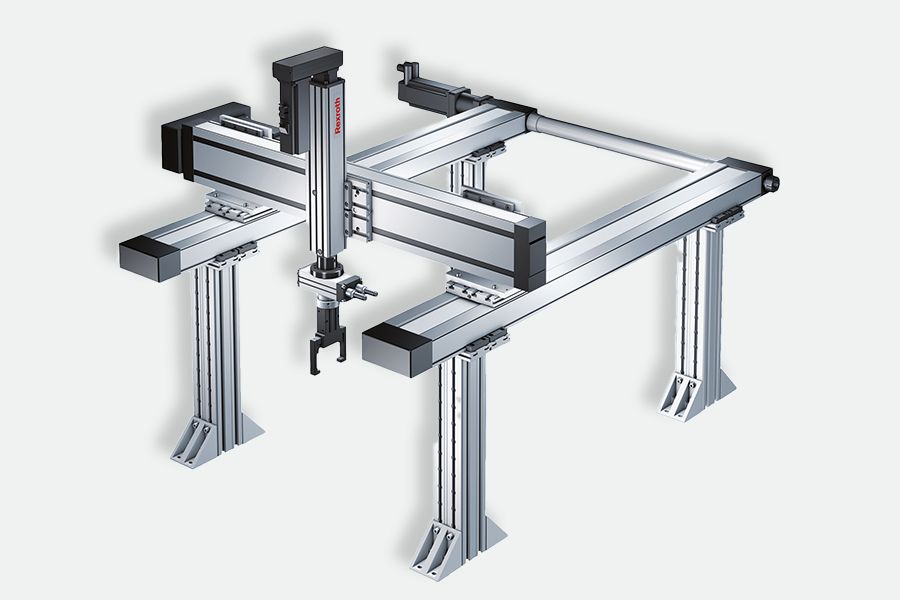

Cartesian robot

for precise handling and efficient automation

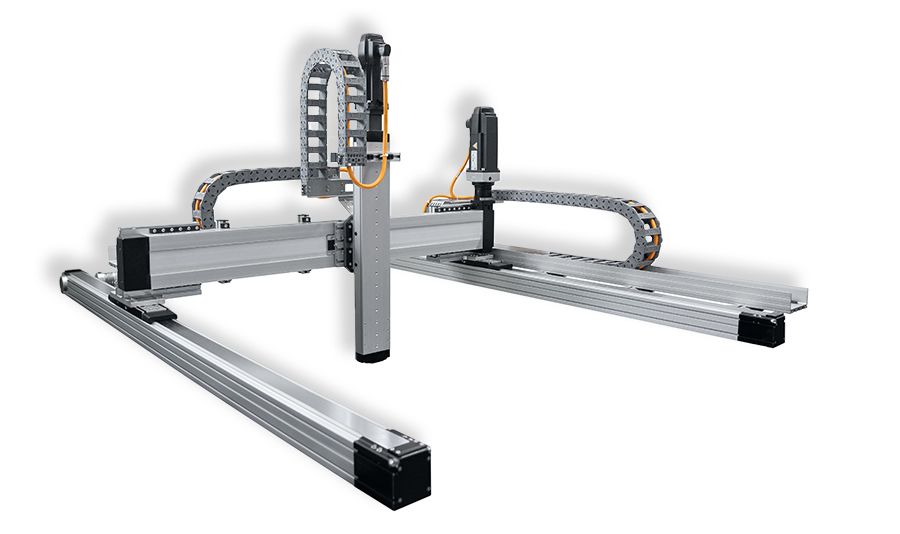

A Cartesian robot – also known as a linear or XYZ robot – is an automated handling system that moves along a Cartesian coordinate system. Thanks to its linear movements along the X, Y and Z axes, it can position and move objects precisely. This makes it ideal for a wide range of tasks in industrial automation.

These robots consist of a robust base frame that supports the three axes. Movement is typically achieved via profile rails, with electric motors driving the axes. The rotational movement of the motors is converted into a precise linear movement by ball screw drives. The result: maximum accuracy and repeatability – crucial for applications such as pick-and-place, assembly or packaging.

Cartesian robots also score highly with user-friendly control systems such as CtrlX, which enable simple programming and quick adaptation to different handling tasks. Their high speed and precision make them particularly suitable for production environments with short cycle times.

Another advantage is that they can be seamlessly integrated into existing production lines and flexibly combined with other automation solutions – such as conveyor belts, machines or sensors.

-

Areas of application & advantages of Cartesian robots

Areas of application & advantages of Cartesian robots

Manufacturing

Packaging

Food industry

Medical technology

Logistics

Efficiency meets versatility

Ihr Ansprechpartner