Transfer system

Transfer systems from Bosch Rexroth offer you economical transport solutions that can be scaled to suit almost any application.

All systems are modular in design. This ensures fast planning and allows existing systems to be easily expanded or converted.

The flexible transfer systems – TS 1, TS 2plus, TS 5, the new TS 7 and the VarioFlow chain conveyor system – differ in dimensions and permissible payloads. They consist of standardized units that can be combined as required to form a system. This enables the design of numerous variants and results in customized systems, tailored to the respective assembly, testing or transport task.

All systems are developed for Industry 4.0 and can be combined with Active Cockpit & ActiveAssist, for example, to support you on your way to a fully automated industry.

Transfer systems from Bosch Rexroth offer you economical transport solutions that can be scaled to suit almost any application.

All systems are modular in design. This ensures fast planning and allows existing systems to be easily expanded or converted.

The flexible transfer systems – TS 1, TS 2plus, TS 5, the new TS 7 and the VarioFlow chain conveyor system – differ in dimensions and permissible payloads. They consist of standardized units that can be combined as required to form a system. This enables the design of numerous variants and results in customized systems, tailored to the respective assembly, testing or transport task.

All systems are developed for Industry 4.0 and can be combined with Active Cockpit & ActiveAssist, for example, to support you on your way to a fully automated industry.

Transfer system TS1

The TS 1 transfer system is specifically tailored to small, lightweight products and assemblies, which require high positioning accuracy and repeatability.

Transfer system TS 2plus

The market leader’s versatile TS 2plus transfer system works reliably, even under difficult conditions, such as in ESD environments and clean and dry rooms.

Transfer system TS2 pv

The focus of the TS 2pv is on cleanroom suitability. The transfer system was specially developed to meet the high demands of a clean production environment.

Transfer system TS5

Modular, reliable, efficient. The roller conveyor system with which higher loads of more than 400 kg can be transported over long distances.

Transfer system TS7

The TS7 transfer system makes it possible to transport the heaviest battery packs up to well over one ton safely and reliably through the assembly.

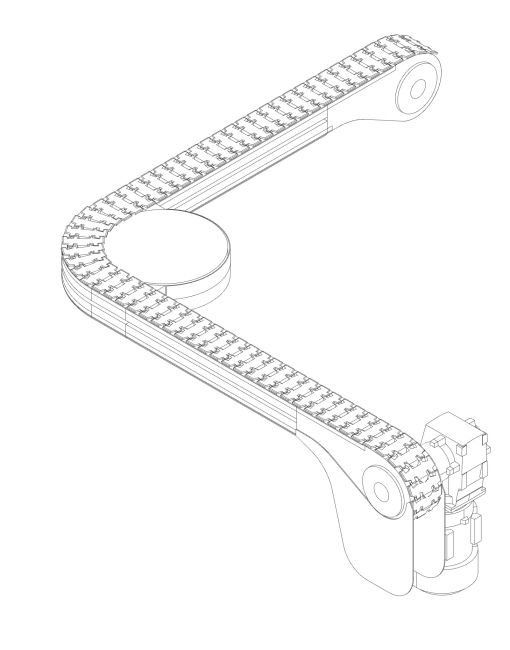

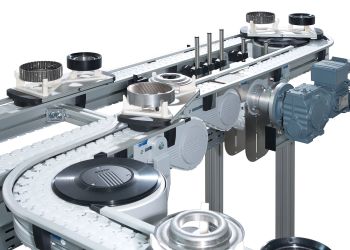

VarioFlow – chain conveyor system

The VarioFlow plus from Bosch Rexroth provides you with a powerful, standardized and versatile chain conveyor.

Your contact