Automation

Increase the quality and efficiency of your production, manufacturing or logistics by automating your processes.

Increase the quality and efficiency of your production, manufacturing or logistics by automating your processes.

will be increasingly important in the future, presenting us with challenges. Downtimes, set-up times, energy consumption and labour costs must be reduced. From consulting to service, we provide you with future-proof automation solutions for your production, manufacturing or dispatch area.

Would you like to relieve your employees? Perform strenuous, monotonous and quality-relevant processes reliably and coordinate them optimally? We can analyse your existing production, manufacturing or intralogistics processes, and then develop and implement efficient automation solutions and optimisations.

Economic efficiency is our top priority. If necessary, machines can be overhauled and optimised with software enhancements or supplemented with additional new systems. Learn more about retrofitting and whether it is worthwhile.

We offer customised automation solutions for your factory from a single source!

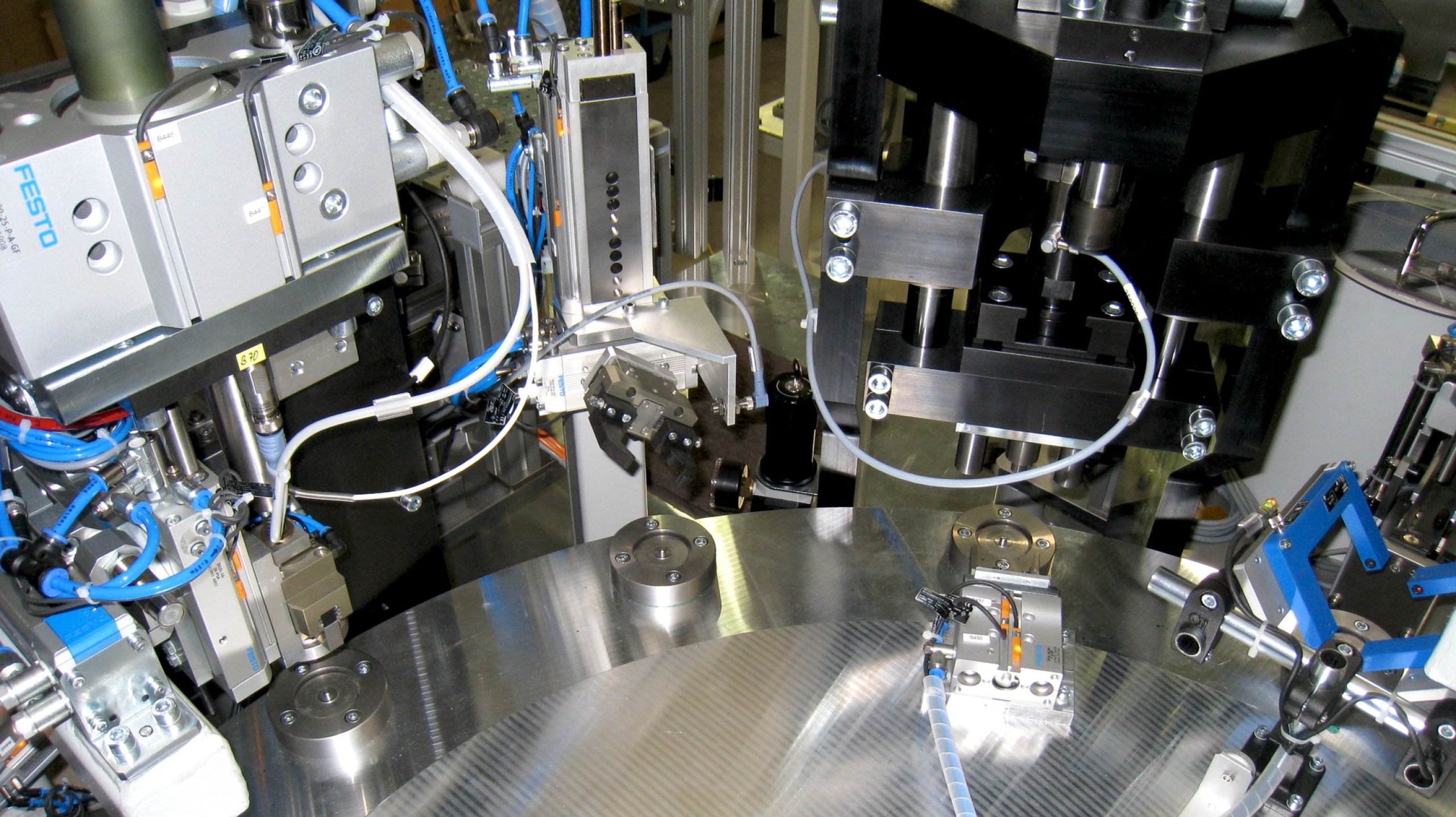

Do you manufacture a range of products and are you looking for highly efficient, product-specific production stations or complex production lines? You can benefit from our modular, scalable automation solutions that are customised precisely to your requirements.

We look forward to working with you to develop innovative, customised solutions for your intralogistics processes, such as partially or fully automated stations and systems, flexible robot or cobot solutions, and autonomous transport systems. For the automation solutions in your factory, we have access to the modular, continuously developed components of assembly, drive and linear technology as well as hardware and software for intralogistics from Bosch Rexroth.

As an integrator, we support you with relevant experience from the automotive industry, e-commerce, electrical industry, laboratory and medical technology and other industrial sectors.

Automation technology provides the basis for reproducible quality and sustainable production processes.

Advantages of automation technology

-

Increased productivityAutomation can shorten production times and increase output at the same time.

-

Higher qualityAutomated processes minimise human error and ensure consistent product quality.

-

FlexibilityModular systems can be quickly adapted to new production requirements.

-

Cost efficiencyReduction of labour costs and material waste through optimised processes.

-

SustainabilityEnergy-efficient systems lower energy consumption and reduce the ecological footprint.

Areas of application for automation technology

-

Automotive industryautomation solutions for assembly lines, testing processes, logistics and material handling.

-

E-commerceEfficient intralogistics and integration of parcel conveyor technology with sophisticated automation solutions for fast order processing and warehousing.

-

Electrical industryPrecise and fast production of electronic components.

-

Laboratory and medical technologyAutomation solutions for analysis, testing and packaging processes with the highest quality requirements.

Quality of automation technology

-

PrecisionState-of-the-art control and sensor technology ensures exact process control.

-

DurabilityRobust materials and high-quality workmanship guarantee a long service life.

-

ReliabilityOur systems offer high availability and low downtimes.

-

Ease of useIntuitive operation and simple integration facilitate use and maintenance.

-

SupportWe offer comprehensive service and training to ensure optimum utilisation.

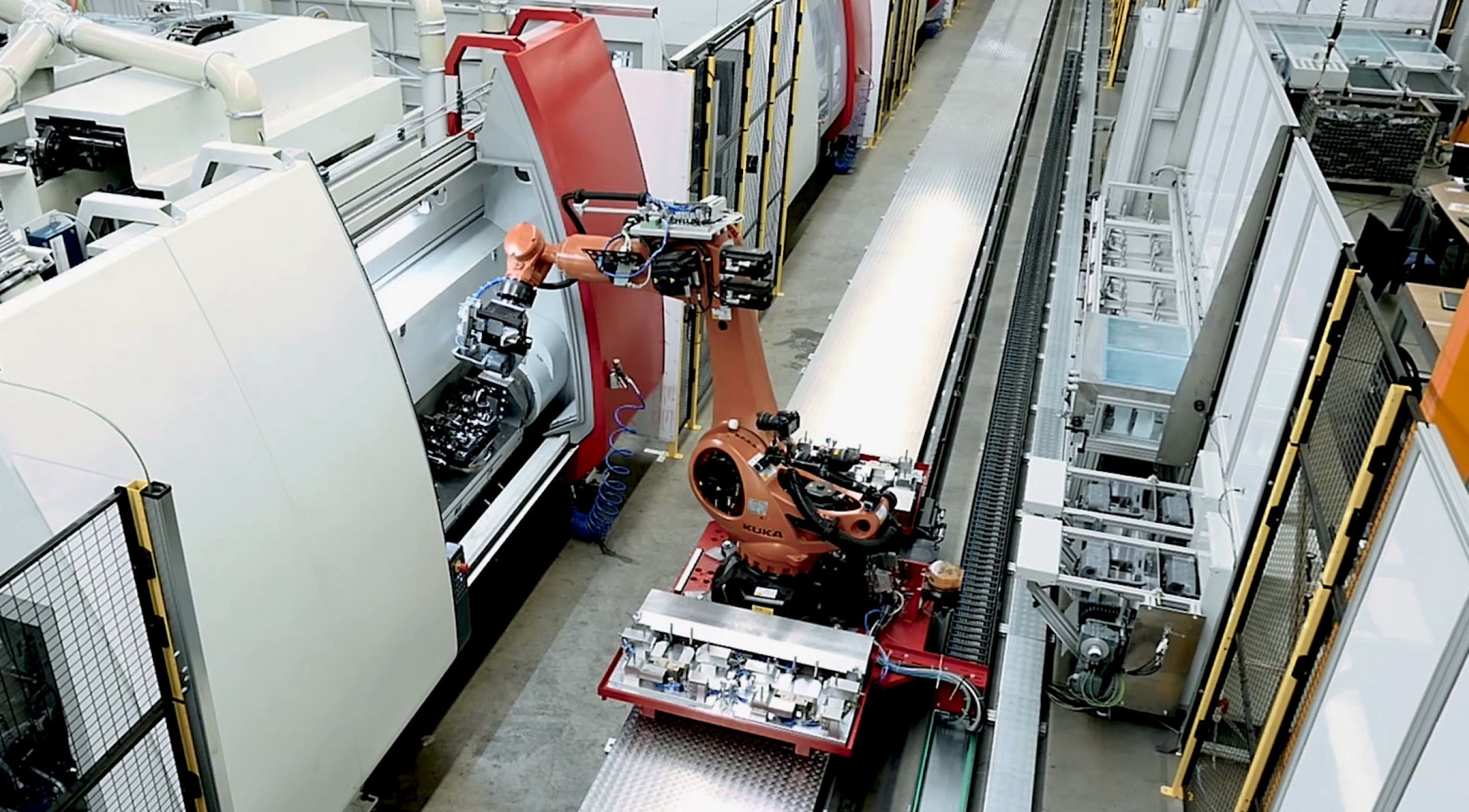

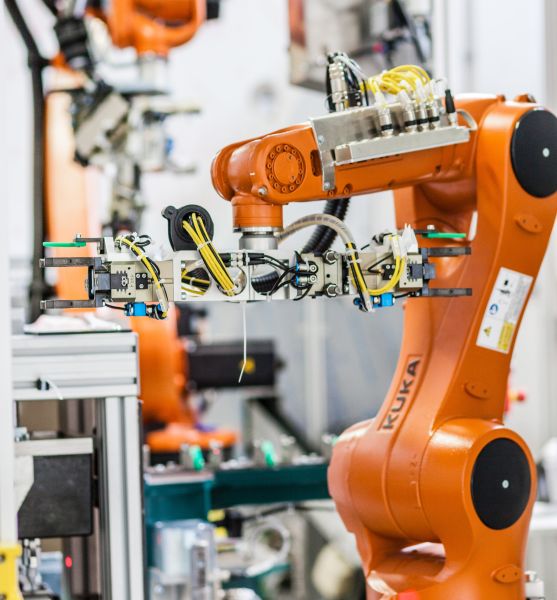

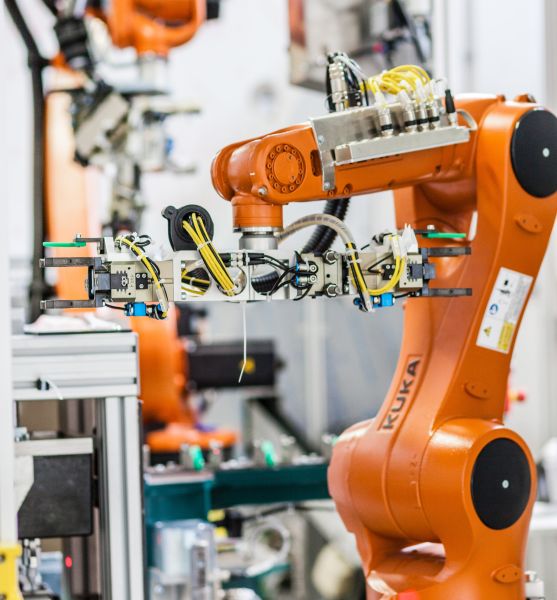

Robot solutions

Quality, availability and performance by using robot technology and robot integration.

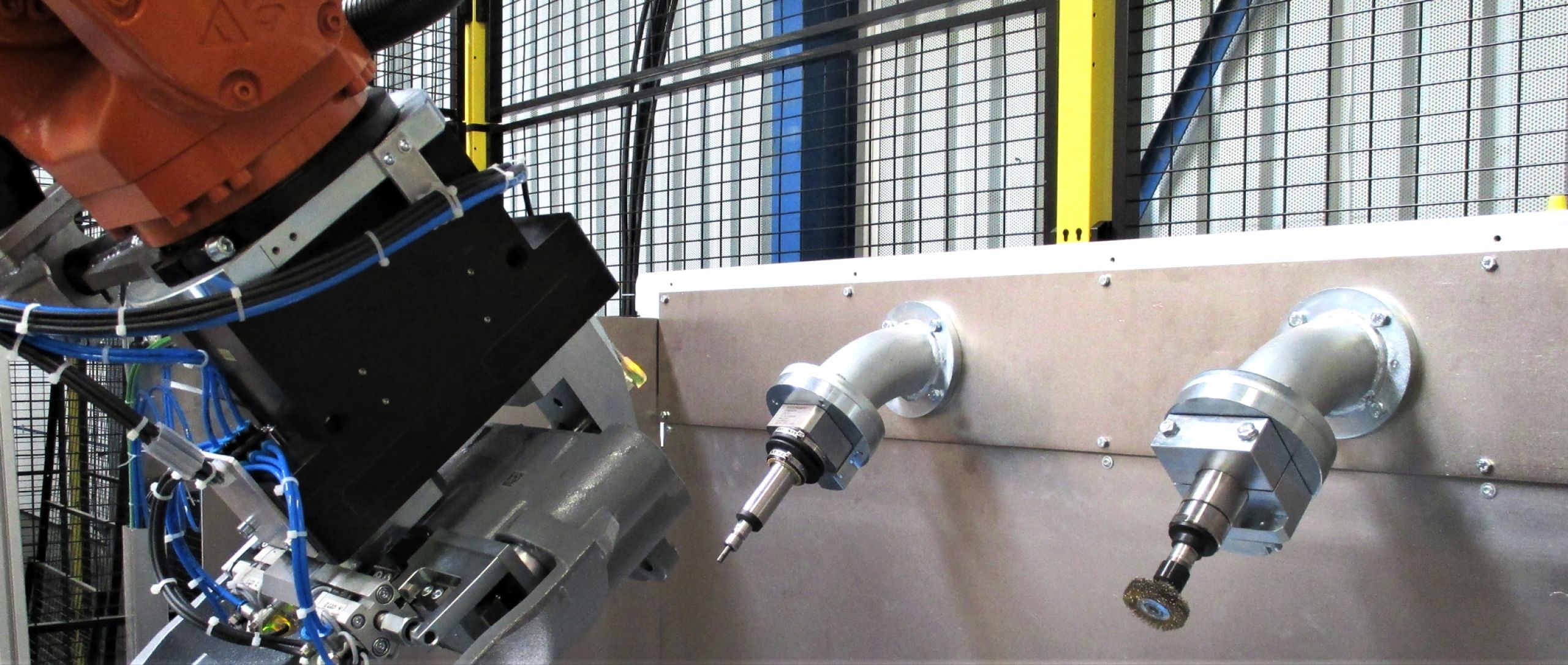

The industrial robots to be integrated are flexibly adapted to your needs and equipped with individually developed grippers. In cooperation with partners who have profound knowledge in image processing, we combine vision systems with robot technology and create individual pick and place solutions.

-

integration of all common robots ABB, Fanuc, Kuka, Yaskawa

-

individual Plug&Play robot cells

-

Robot platform

-

Robot 7th axis

Plug&Play Robot Cells

Simple, flexible and versatile.

Are you looking for an individual turnkey solution that is easy to install, increases your productivity and at the same time relieves your employees?

We look forward to your inquiry.

Smart Flex Effector

Equip your robot with the sensor-based end effector from Bosch Rexroth, for example, and increase precision. Equipped with an active measurement function in six degrees of freedom, the compensation module is ideally suited for handling and joining processes with tight tolerances.

Robot integration in production lines

Industrial Robotics

Collaborating robots

Automated guided vehicles

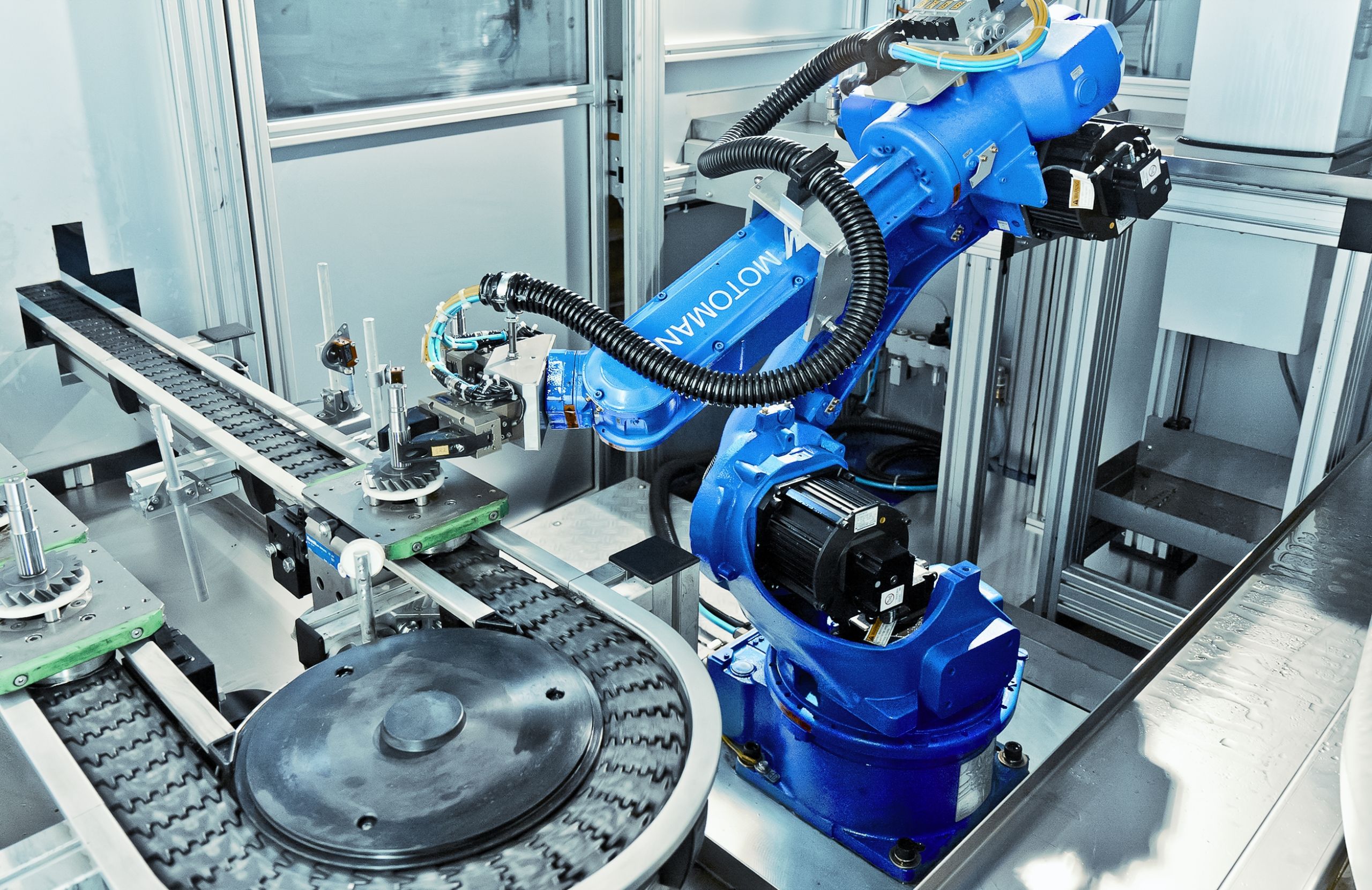

Solutions for measuring and testing

Ensure the quality of your workpieces or components by using semi-automatic or fully automatic measuring or testing stations, which guarantee 100% quality control in the shortest possible time. We also develop specific automation solutions that are precisely tailored to your inspection tasks.

As you know, even the smallest production errors in manufactured parts can have cost-intensive consequences. Let us analyse your specific quality inspection process together to see if automation is possible and economically feasible.Depending on the scope of the measurement and testing task, we can implement tactile, optical, electrical, flow and leak tests in collaboration with specialised partners. We can also integrate this technology, which is developed specifically for this purpose, into our stations and systems. Our intelligent automation solutions seamlessly integrate these testing processes into your existing workflows.

Your contact