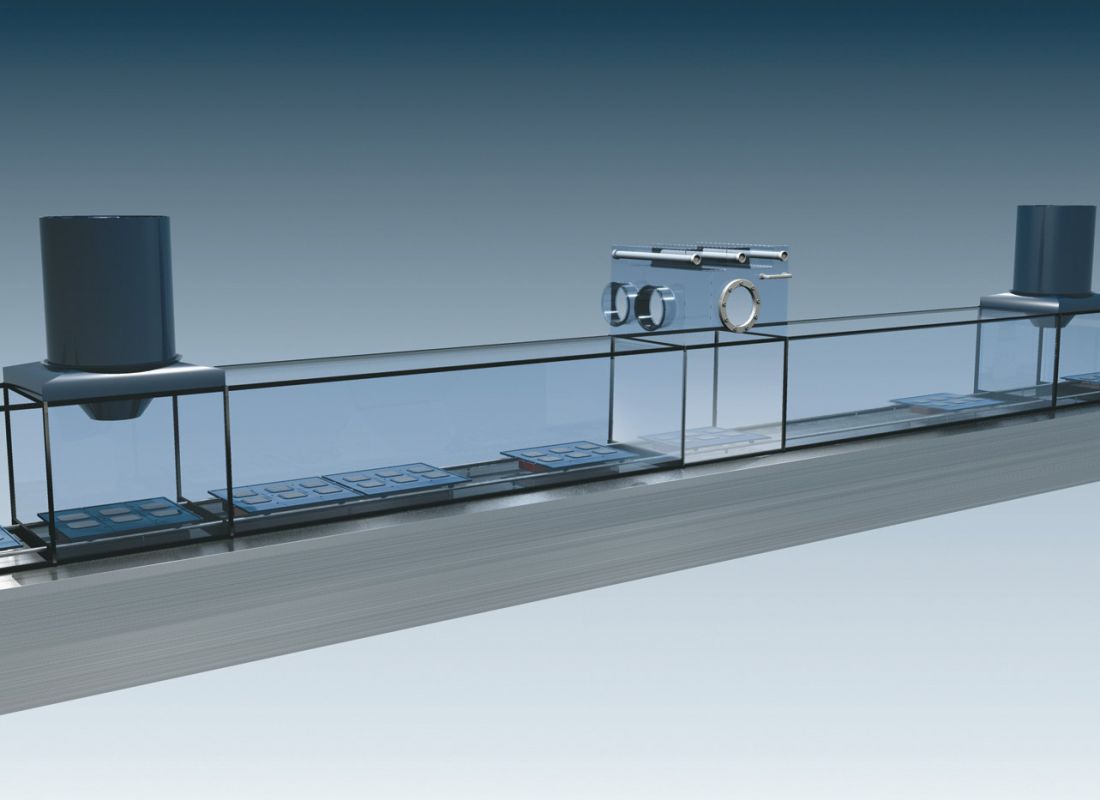

Bosch TS2 pv transfer system

- Depending on the respective module dimensions, the individual segments are usually two to three meters long, 0.6 to 1.5 meters wide and made up of two to five tracks.

- Each segment has its own drive.

- The drive stops to position the module for processing or if the following line segment is still occupied by another module.

- Frequency inverters ensure smooth braking and acceleration.

- The LTS lift transverse unit gently transfers the modules from longitudinal to transverse sections.

-

Advantages

Advantages

Weight

Individual systems implemented quickly and cost-effectively

Gentle material flow

Minimal corrections to the final position of the solar modules on the conveyor line

Transport of glass plates at temperatures of up to 160 °C

Can be realized with up to 5 tracks, individually adapted to the size of the solar panel

-

Areas of application

Areas of application

-

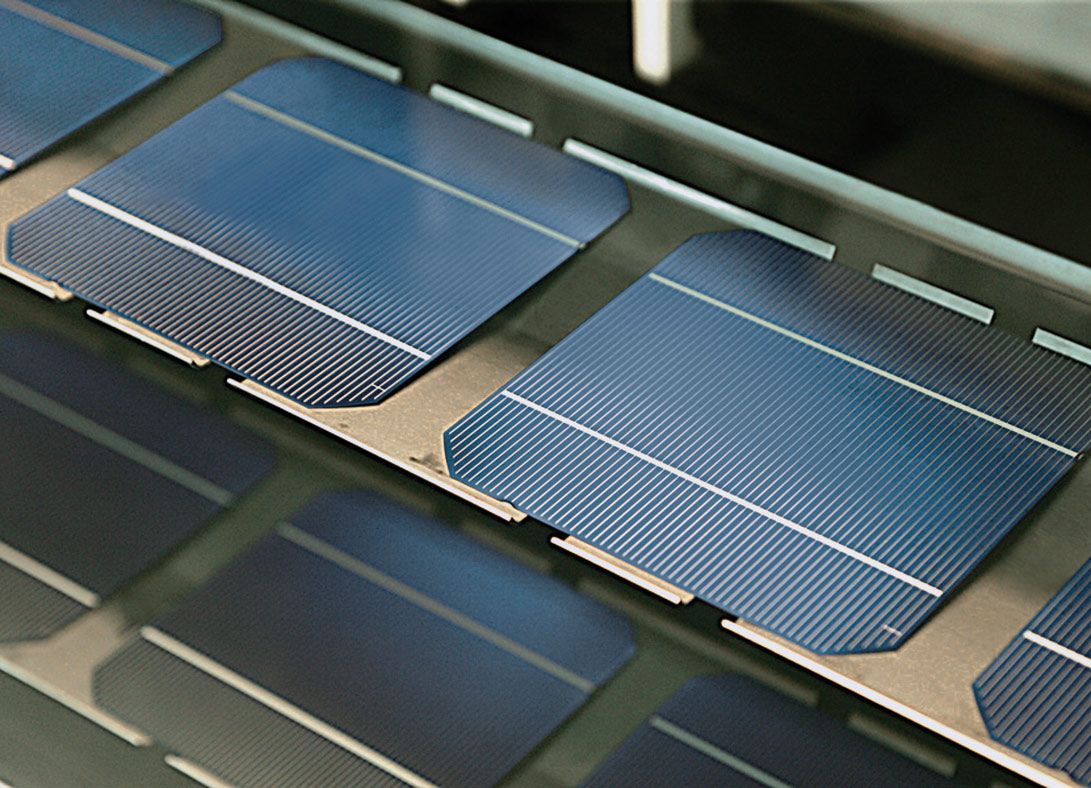

Solar module productionThe Bosch TS2 pv is particularly indispensable in the production of wafer-based and thin-film solar modules, as it ensures impact-free, efficient transportation and precise handling of the sensitive glass plates.

-

Clean room environmentsIn solar module manufacturing, the cleanliness of the production environment is crucial for product quality. The Bosch TS2 pv has been specially designed for use in cleanrooms and meets the requirements for cleanroom suitability. This prevents dust or other contaminants from affecting the solar modules during the manufacturing process. Other processes that require a cleanroom environment include semiconductor production (chip production), pharmaceutical production (e.g. vaccines, sterilized medicines), the manufacture of medical devices and implants (e.g. pacemakers) or surgical instruments, nanotechnology and microsystems technology (MEMS) and optical production (e.g. lenses, lasers)

-

Production lines with high temperature stability requirementsAs the system works efficiently even at high temperatures of up to 160 °C, it is ideal for processes in which the glass plates have to be transported during or after thermal processes, such as after lamination or coating.

-

Quality and reliability

Quality and reliability

The Bosch TS2 pv offers outstanding quality and reliability, specially developed for the demanding conditions of the solar industry. The robust design and high-quality materials guarantee a long service life and stable operation, even under extreme conditions. The system minimizes the need for frequent maintenance, thereby reducing operating costs.

The cleanroom suitability of the system ensures that no impurities that could affect the quality of the solar modules occur during the entire production process. This contributes to consistently high product quality and ensures that the production results meet the stringent requirements of the solar industry.

The Bosch TS2 pv is therefore not only an economical, but also a highly precise and reliable solution for the solar industry. It enables solar modules to be manufactured quickly and efficiently while maintaining the highest quality standards, helping to reduce production costs and increase productivity.